Optimize the supply chain with forecasting and demand planning

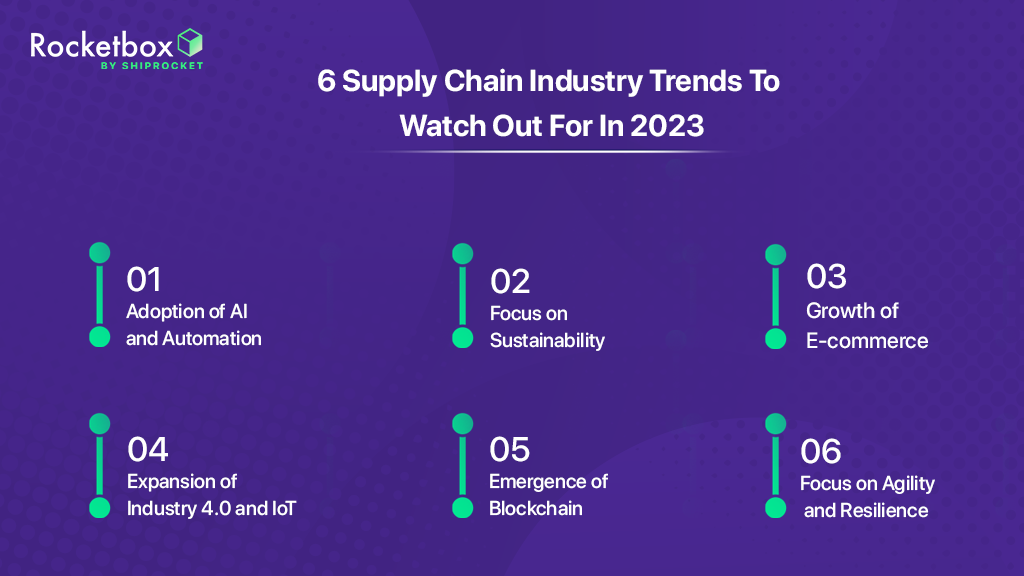

Strong Supply Chains across industries kept the world running during the peak years of Covid-19. However, with technological improvements, shifting consumer behavior, and new business models, the supply chain industry is anticipated to experience some major changes in 2023 and beyond. Automation and artificial intelligence will be used more frequently, vastly improving operations and streamlining supply chain management. As businesses work to reduce their carbon impact and make sure that their supply chains are socially responsible, sustainability and ethical behavior will also be in the focus.

Source: Shiprocket

Retailers will be driven to adapt as e-commerce and omnichannel retail continue to expand as consumers seek seamless shopping experiences across a variety of platforms.

The Future of Demand Planning and Forecasting in the Supply Chain

Demand planning is a vital process in supply chain management that involves forecasting or predicting the expected demand for products. The purpose of demand planning is to ensure that products can be delivered on time to meet customer demand and satisfaction.

The supply chain’s demand planning and forecasting will be influenced by technological improvements, rising consumer desire for customization and personalization, and more environmentally friendly and sustainable business practices. Here are some significant trends and advancements to keep an eye on:

- Use of artificial intelligence and machine learning: AI and ML can assist in identifying patterns and trends in data that may be challenging for people to discover, enhancing prediction accuracy and allowing companies to react more swiftly to changes in demand.

- Demand Sensing involves detecting and reacting to changes in demand using real-time data. Swiftly modifying production and inventory levels in response to shifting consumer demand enables businesses to be more nimble and responsive.

- Personalization and customization: Customers now demand that goods and services be adapted to their specific requirements. This trend is likely to continue, and demand planning and forecasting must take into account the complexity and variety of client demand as it rises.

- Sustainable and Environmentally Friendly Practices: For firms to achieve their sustainability objectives, demand planning and forecasting will need to consider elements like carbon footprint, ethical sourcing, and circular supply chains.

- Coordination and Integration: Demand forecasting and planning will be more closely coordinated with other supply chain activities like production scheduling, inventory control, and logistics. Enable seamless data exchange and analysis, this will demand better collaboration and communication between various teams and processes.

Overall, the future of demand planning and forecasting in the supply chain is likely to be characterized by increased use of technology, greater customization and personalization, a focus on sustainability, and closer collaboration and integration between different functions within the supply chain.

Benefits of demand planning and Forecasting in the supply chain

Demand planning and forecasting are essential elements of supply chain management that can assist firms in various ways. Here are some figures that illustrate the benefits of these actions:

- Better Inventory Management: A McKinsey analysis claims that good demand planning can cut inventory expenses by as much as 30% and increase inventory turns by as much as 20%.

- Cost savings: According to research by APICS, businesses with efficient demand planning and forecasting procedures saw a 15% drop in inventory expenditures, a 17% rise in the percentage of orders that were ideal, and a 35% drop in stock-outs.

- Improved Customer Service: According to research by Aberdeen Group, businesses with best-in-class demand planning procedures saw increases in customer order fill rates of 12% and on-time delivery rates of 15%.

- Better Decision-Making: According to a Gartner analysis, organizations with efficient demand planning and forecasting processes saw a 2-5% increase in prediction accuracy, which can enhance decision-making and reduce waste.

- Competitive Advantage: According to a Deloitte poll, 66% of firms invest in demand planning and forecasting technologies to gain an advantage over their rivals. 70% of organizations consider demand planning a key competitive advantage driver.

Forecasting and demand planning can provide significant benefits for businesses, including improved inventory management, cost savings, enhanced customer service, better decision-making, and a competitive advantage in the market.

Strategies to Improve Forecasting and Demand Planning

- Actionable insights into demand patterns, seasonality, and other factors that can lead to more precise forecasts can be found in historical data and trends. Machine learning and other advanced analytics techniques can be used to find trends and improve prediction accuracy.

- The possibility of erroneous projections can be reduced by combining qualitative and quantitative forecasting techniques. This can include market research, professional judgment, and statistical models. Harvard Business Review as a source

- Including real-time data in forecasting models, such as weather patterns, social media fads, and economic indicators, enables businesses to modify forecasts in real time. (Supply Chain Dive as Source)

- Collaborating with suppliers and customers can help improve forecasting accuracy and enable greater visibility into supply chain dynamics. This can include sharing data, conducting joint forecasting exercises, and implementing vendor-managed inventory (VMI) programs. (Source: Harvard Business Review)

- Monitor and adjust forecasts regularly forecasts should be regularly reviewed and adjusted based on actual demand and other changing factors. This can help minimize the risk of stockouts or excess inventory and enable greater responsiveness to customer needs. (Source: Deloitte)

Conclusion

We at Polestar Solutions specialize in helping to optimize your Supply Chain with the help of service offerings like Anaplan, Data Management & Analytics, and Business Intelligence. At Polestar Solutions, our team of Anaplan experts has the experience and expertise in consulting and implementing Anaplan for Fortune 500 clients, unicorns, and small to medium enterprises globally. Our team of Anaplan solution experts has built solutions for every domain of your business – from Effective Inventory Management, Supply Network Optimization, Capacity Planning, Production Planning, and Sourcing Planning.